Fin tube are a type of heat exchanger that is used in many different industries. These tubes have a finned surface, which increases their surface area and allows them to transfer heat more efficiently. This makes them ideal for applications where high heat transfer rates are required, such as in power plants and refrigeration systems.

Fin tubes are made from a variety of materials, including copper, aluminum, and stainless steel. They are available in a range of sizes and shapes and can be customized to meet the specific needs of each application.

One of the key benefits of fin tubes is their ability to operate efficiently at high temperatures and pressures. This makes them suitable for use in a wide range of applications, including air conditioning, heat exchangers, and radiators.

In addition to their high thermal performance, fin tubes are also durable and long-lasting. They are resistant to corrosion and can withstand the harsh environments often found in industrial settings. This makes them a cost-effective solution for many different industries.

Increase Heat Transfer Rate

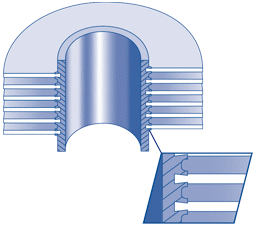

A finned tube exchanger typically has tubes with fins attached to the outside. Usually, there will be some liquid flowing through the inside of the tubes and air or some other gas flowing outside the tubes, where the additional heat transfer surface area due to the finned tube increases the heat transfer rate.

In a crossflow fin tube exchanger, the fins will typically be radial fins and they’ll either be circular or square in shape.

Improve Heat Transfer Coefficient

By not using a finned tube, the outside surface area is not significantly greater than the inside surface area. Because of this, the fluid with the lowest heat transfer coefficient will dictate the overall heat transfer rate. When the heat transfer coefficient of the fluid inside the tube is several times larger than that of the fluid outside the tube, the overall heat transfer rate can be greatly improved by increasing the outside surface area of the tube.

Increase Outside Surface Area

By having a finned tube in place, it increases the overall heat transfer rate. Finned tubes increase the outside surface area. This decreases the total number of tubes required for a given application which then also reduces overall equipment size and can in the long-run decrease the cost of the project.

Finned tube heat exchangers are used in a variety of applications, and more so as industrial heat exchangers. An air heat exchanger like the evaporator coil in an air conditioning unit is typically a fin tube exchanger. Another common fin tube air heat exchanger is the car radiator. The purpose of the car radiator is to cool the hot water in the tubes with the air passing through the crossflow.

On the contrary, the air conditioner evaporator coil has the purpose of cooling the air passing through it. The finned tubes that are manufactured at Kainon Boilers, use high grade carbon steel, stainless steel, copper, brass, and aluminum. Our finned tube exchangers are designed to meet the specific duty condition, temperature and pressure of the fluids.

Fin tube boilers represent one of a number of pressurized equipment options used to heat water or convert water into steam under controlled conditions. As in a water tube boiler, water passes through boiler tubes while combustion gases remain in the shell side, passing over the tube surfaces.

Fin tubes are used in applications involving the transfer of heat from a hot fluid to a colder fluid through a tube wall. Furthermore, finned tubes are used when the heat transfer coefficient on the outside of the tubes is appreciably lower than that on the inside.

Some fin tube types are:

Type of Fin Tube | Fin Tube Properties |

| |

| |

| |

| |

|

if you ever have a concern, question or comment please contact us and we will be more than happy to assist you to answer all your questions.

Address :

Jl. K.H. Zaenal Mustafa No. 17

Jatinegara Jakarta Timur 13350

Phone : 62 21 8561234 ( Hunting )

Fax : 62 21 8513109

E mail : info@fintubes.co.id