What is KL Type Fin Tube|KLM Finned Tube?

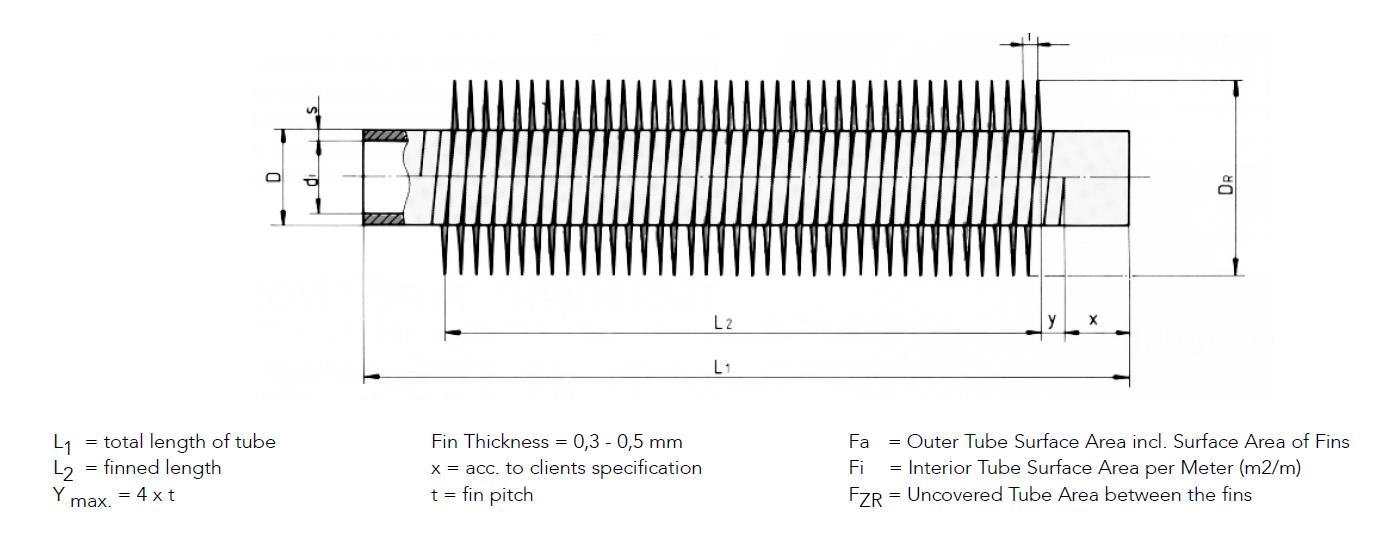

KL type finned tube is a kind of finned tube with knurled on bare tube. Also called Knurled L type finned tubes. Before winding the fins, there is a blade knurl patterns on the base tube, and use the back blade winding fin strip on the tubes. The finned tube made knurling and winding at the same time.

KL Type Fin Tube|KLM Finned Tube|Knurled L Type Finned Tube

The KL Type Finned Tube relies on maximum surface contact between the fins and the tube, which is ensured by the tension of the fin strips helically forming around the pre-knurled tube, providing improved bonding and heat transfer. The maximum working temperature of KL Type Finned Tube can reach 250°C, and the maximum working pressure can reach 3.2MPa.

Advantages: Core tube extensively protected against corrosion by the fin foot, finning of very thin-walled tubes possible.

KL Type Fin Tube|KLM Finned Tube|Knurled L Type Finned Tube Material Combinations

Core Tube: Carbon steels low-alloy steels, stainless steels, brass, copper, copper-nickel alloys, aluminium bronze, nickel-alloys (Alloy 400 ext.), bimetal, titanium and others

KL Type Fin Tubes Fins: Aluminium, Copper

KL Type Fin Tube|KLM Finned Tube|Knurled L Type Finned Tube Fields of Application:

• the petroleum, chemical and petrochemical industries

• natural gas treatment

• the steel industry: blast furnace and converter systems

• power generation: steam turbine exhaust condensing

– contact condensing with cooling of circulating condensate

– fossil and nuclear power plants

• air conditioning (freon, ammonia, propane)

• incineration of household refuse

• compressor coolers, ect.

KL Type Fin Tube|KLM Finned Tube|Knurled L Type Finned Tube Manufacturing Process

The manufacturing strip is folded to from an L shape and then wound around the base tube. The feet of the fins are joined together and cover the whole of the finned surface. Both ends are clamped down to avoid unrolling through damage. Before winding the fins, there is a blade knurl patterns on the base tube, and use the back blade winding fin strip on the tubes. The finned tube made knurling and winding at the same time.

KL Type Fin Tube|KLM Finned Tube|Knurled L Type Finned Tube Advantages

Economic: This method of manufacturing enables us to place the finning on a very thin-walled tube with is particularly desirable when using high value alloys (titanium, stainless, copper, nickel). The tube can withstand a temperature of up to 130°C without the risk of atmospheric corrosion or thermal stress.

Address :

Jl. K.H. Zaenal Mustafa No. 17

Jatinegara Jakarta Timur 13350

Phone : 62 21 8561234 ( Hunting )

Fax : 62 21 8513109

E mail : info@fintubes.co.id