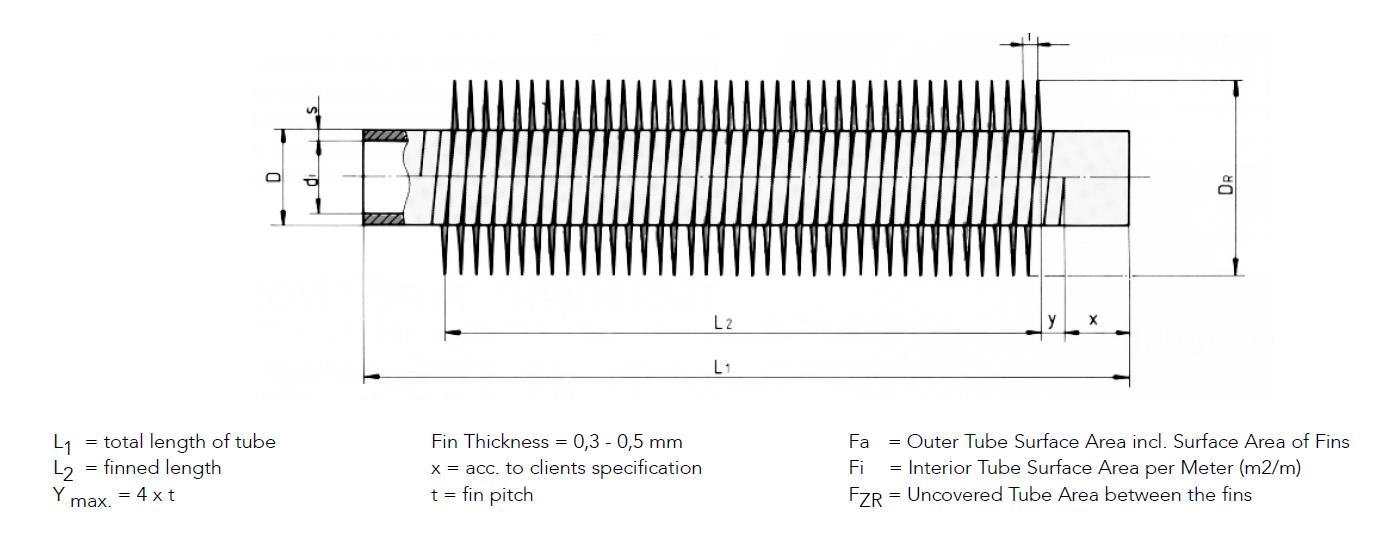

G Type Fin Tube| Embedded Finned Tube

G Fin Tube discription: The fin strip is wound into a mechanically produced groove and tightened by backfilling of the base material under pressure.

Groove depth appr. 0,4 mm.

G Fin Tube advantages: High fin stability, excellent heat transfer, high operating temperature.

G Type Fin Tube Material Combinations

G Type Fin Tube Material Combinations

G Fin Tube Core Tube: Carbon steels, low-alloy steels, stainless steels, brass,copper, copper-nickel alloys, aluminium bronze, nickel-alloys (Alloy 400, etc.), bimetal, titanium and others

G Fin Tube Fins: Aluminium / Copper / Steel / Galvanized Steel

G Type Fin Tube Fields of Application:

• the petroleum, chemical and petrochemical industries

• natural gas treatment

• the steel industry: blast furnace and converter systems

• power generation: steam turbine exhaust condensing

– contact condensing with cooling of circulating condensate

– fossil and nuclear power plants

• air conditioning (freon, ammonia, propane)

• incineration of household refuse

• compressor coolers, ect.

G Type Fin Tube Manufacturing Process

The manufacturing tool is made up of 2 non-cutting plates set at 90° to the axis of the base tube. The first plate effects a groove for metal spinning. The second directs the ribbon in the groove and sets the fin foot in the groove through pressure on the metal displaced for the groove. A similar plate made of tungsten carbure allows us to manufacture G finned tubes with base tubes made of austenitic steel or exotic alloys.

G Type Fin Tube Advantages

1) G Fin Tube Thermal

The fin/tube wall contact is constant because of the setting and makes it possible to use a wall temperature of up to 400° C.

2) G Fin Tube Mechanical

The fin is set throughout its length and consequently does not unwind even when partially uprooted.

Address :

Jl. K.H. Zaenal Mustafa No. 17

Jatinegara Jakarta Timur 13350

Phone : 62 21 8561234 ( Hunting )

Fax : 62 21 8513109

E mail : info@fintubes.co.id