What is studded Tubes or Studded Pipes?:

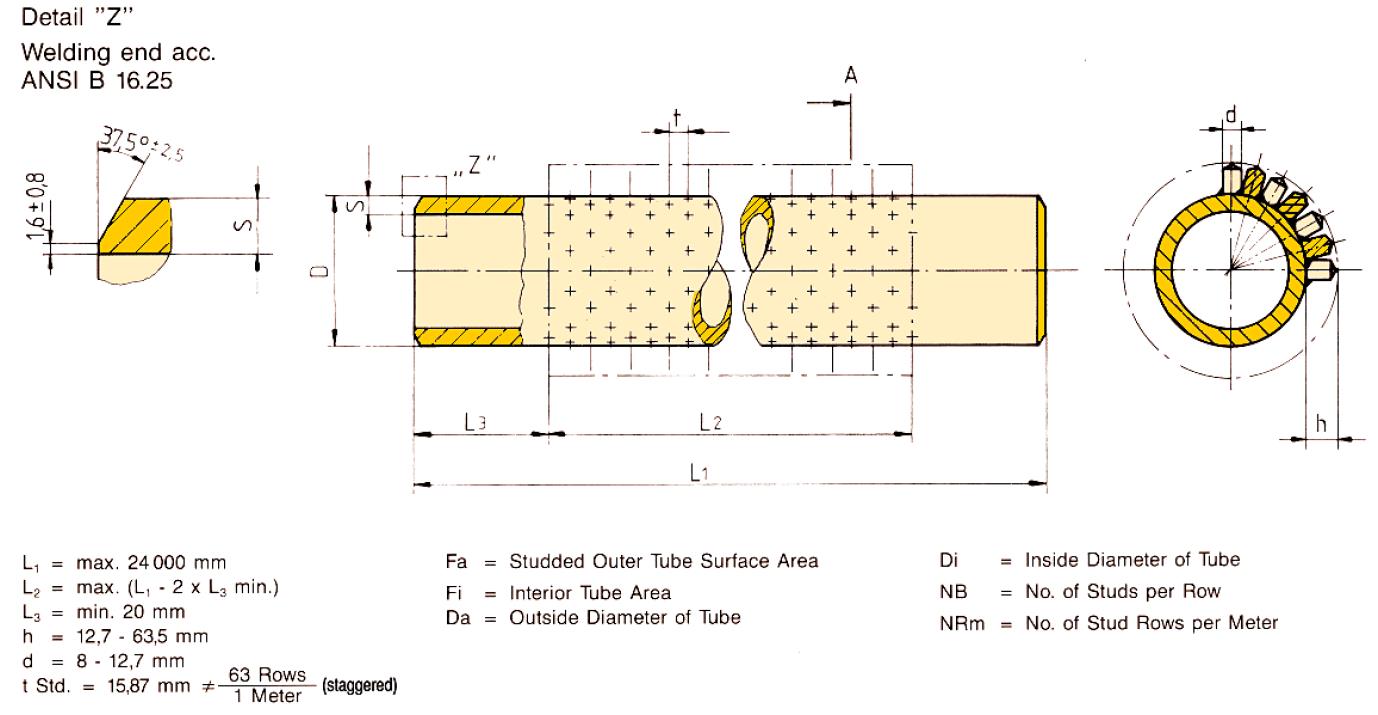

The studs are welded on the tubes using electrical resistance welding, producing high quality welds. Studded tubes have better preference than finned tubes in heat transfer systems in petrochemical plants, where the surface is exposed to very corrosive environment such as dirty gases or liquids. These tubes should be resistant to aggressive materials and must be cleaned frequently.

Studded Tubes Materials: Base Tube & Studs

Carbon Steels, Low Alloy Steels, Stainless Steels

Studded Tubes Sizes:

Studded Tubes Sizes:

The Standard Tube Dimensions given in the above table are taken from typical orders. We produce studded tubes also with other base tube dimensions in the range 60,3 up to 219,1 mm Outside Diameter.

Up to 24 meters. If necessary with circumferential weld, 100% x-rayed. If required pressure tested.

Studded Tubes Studs

Standard Stud row spacing 5/8″ (15,88 mm) = 63 Stud rows per meter, other spacings on request

Studded Tubes Type of Studs

Cylindrical , elliptical or lens type

Studded Tubes Fields of application:

Furnaces-, Chemical-, Petrochemical-Industry, Power stations etc. where liquid media under high pressure are to be heated or cooled.

Studded Tubes Manufacturing process:

Studs are fully automatically welded onto the tube by resistance welding.

Studded Tubes Advantages:

Due to their high rigidity, studded tubes can be used even under extreme temperature and pressure conditions.

Address :

Jl. K.H. Zaenal Mustafa No. 17

Jatinegara Jakarta Timur 13350

Phone : 62 21 8561234 ( Hunting )

Fax : 62 21 8513109

E mail : info@fintubes.co.id